whole process titanium production line

Through innovative technologies, process, and equipment, we make the titanium production process simplified and more efficient by our production revolution.

1. Raw Material

1. Raw Material

1. Raw Material

- Automatic Mixing System

- Hydraulic Press ( 3500T, 8000T )

- Vacuum Plasma Welding Chamber

*all equipment is for titanium production only

2. Melting

1. Raw Material

1. Raw Material

- EB Furnace: 10T

- VAR Furnace: 10T, 6T, 3T, 1T

*all equipment is for titanium production only

3. Forging

1. Raw Material

3. Forging

- Forging Press: 8000T

- Forging Press: 2000T

- Forging Press: 800T

*all equipment is for titanium production only

4. Rolling

5. Surface Treatment

3. Forging

- BD1350 /BD850 /BD600 Rolling Mill

- KOCKS brand Continuous Rolling Mill

*all equipment is for titanium production only

5. Surface Treatment

5. Surface Treatment

5. Surface Treatment

- Automated Peeling, Polishing, and Grinding line.

*all equipment is for titanium production only

6. Inspection

5. Surface Treatment

5. Surface Treatment

- Fully Automatic Online High-speed Inspection Line

- Ultrasonic Flaw Detection System

*all equipment is for titanium production only

- strive for perfect production revolution

EB + VAR Alloy Ingots

0.1mm Hot Rolling Accuracy , High Precision of "h6"

Production from Ingot to wire & rod within 24hrs

- MAX ROLLED BAR: 350mm

- YIELD MAX: 90%

*all equipment is for titanium production only

Production from Ingot to wire & rod within 24hrs

0.1mm Hot Rolling Accuracy , High Precision of "h6"

Production from Ingot to wire & rod within 24hrs

- LENGTH MAX: 40mm

- COST REDUCTION: 20-30%

*all equipment is for titanium production only

0.1mm Hot Rolling Accuracy , High Precision of "h6"

0.1mm Hot Rolling Accuracy , High Precision of "h6"

0.1mm Hot Rolling Accuracy , High Precision of "h6"

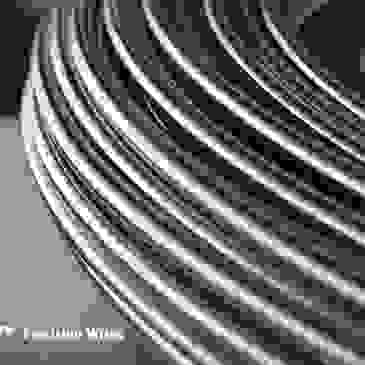

- SIZE RANGE: 1mm - 500mm

- TITANIUM COIL WT: 200KG

.png/:/cr=t:8.34%25,l:3.23%25,w:80.65%25,h:80.65%25/qt=q:1/rs=h:100)